What raw materials are needed to make charcoal

The charcoal machine efficiently converts biomass raw materials into environmentally friendly charcoal, which is widely used in industry, agriculture and life.

Which raw materials can make charcoal

- Wood: This is the main raw material for making charcoal, especially hard broadleaf wood, such as maple, elm, etc. These woods have high density and good burning performance.

- These woods have high density and good burning performance. Softwoods (e.g. pine, cypress) and coniferous woods (e.g. horsetail pine, red pine) can also be used to make charcoal.

- Agricultural and forestry wastes: such as rice straw, corn stalks, peanut shells, coconut shells, palm kernel shells, etc. These materials can also be used as raw materials for charcoal, and are especially suitable for the production of environmentally friendly charcoal.

- Fruit shells and kernels: such as coconut shells, peach kernels, etc. These materials can be used to make kernel charcoal, which has good adsorption properties.

- Bamboo: Bamboo charcoal is a special kind of charcoal, made from bamboo, with a porous structure and good adsorption properties

- Mechanism carbon: made from sawdust, peanut shells, corn cobs, etc. crushed into particles of less than 10mm, dried and put into the carbonization furnace to carbonize and become

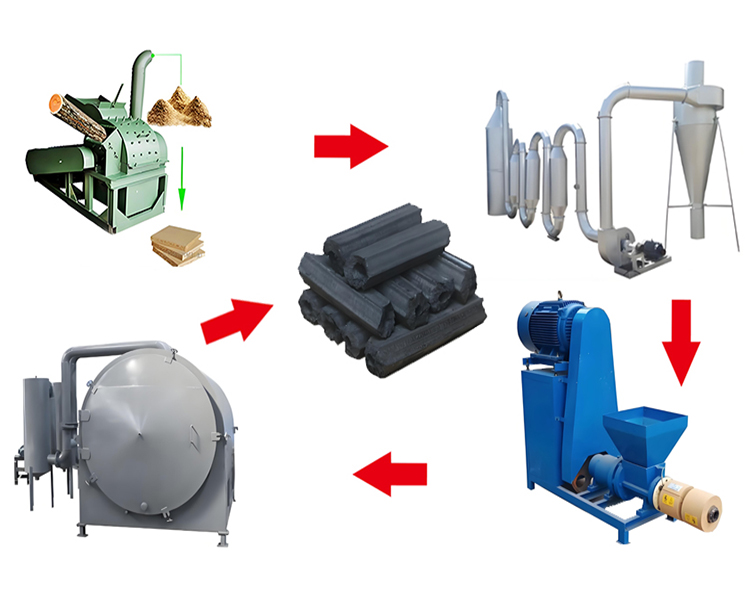

Process flow of charcoal machine

- Crusher: Crush the raw materials (such as wood, straw, bamboo chips, etc.) to less than 10mm particles, the power is about 22KW, the output can be up to 1 ton / hour

- Dryer: to remove the moisture of raw materials (need to be controlled at 8%-12%), using a double cylinder double-layer pipeline heating, power about 11KW

- Rod molding machine: extrusion molding of dried raw materials into rods, equipped with wear-resistant alloy materials, output of about 300KG/hour

- Charcoal Furnace: Charcoal sticks under high temperature and lack of oxygen environment to form high-density charcoal, the power is about 1.1KW, support 24 hours continuous production

Application areas of charcoal machine

- Industrial Uses:

- Smelting of non-ferrous metals, carburizing of mechanical parts, gunpowder preparation, graphite making

- As raw material of activated carbon, used in pollution control, drinking water purification, etc.

- Agriculture & Livestock:

- Soil improvement, moisture retention, slow release pesticide fertilizer

- Deodorizes and enhances digestion of livestock

- Life Use:

- Home heating, barbecue, hot pot fuel

- Dehumidifying, regulating humidity, eliminating harmful substances

Through the four-step process of crushing, drying, molding and carbonization, the charcoal machine efficiently transforms biomass raw materials into environmentally friendly charcoal, which is widely used in industry, agriculture and life. Its features of automation, low pollution and resource recycling make it a key equipment for sustainable development.

Fude Machinery-wood crusher manufacturer

Fude Machinery-wood crusher manufacturer

HelloPlease log in