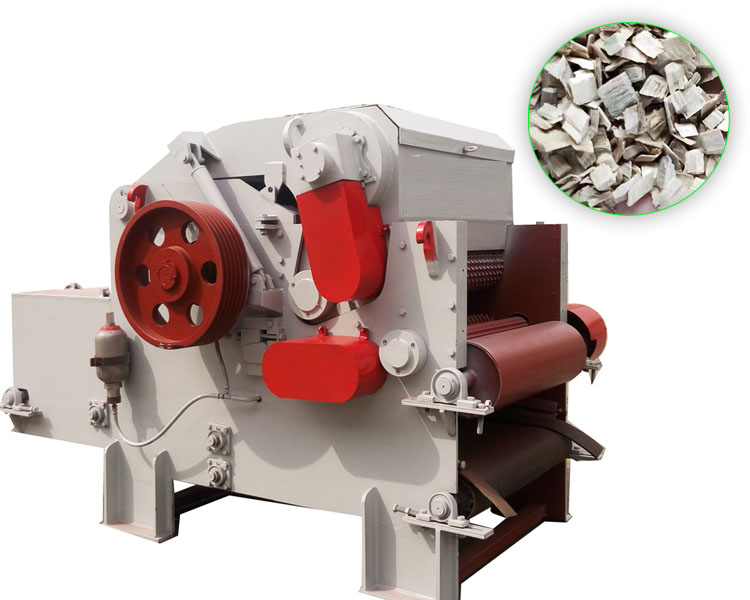

drum chipper machine

drum chipper

drum wood chipper machine is a specialized equipment for making wood chips, widely used in the production of wood chips in papermaking, particleboard, high-density fiberboard factories. It can cut high-quality industrial wood chips such as logs and small diameter wood with uniform length, flat cut, and uniform thickness. It can also cut branch materials, boards, etc.

| Model | 215 | 216 |

| Blade roller diameter (mm) | 500 | 650 |

| Inlet size (mm) | 240×400 | 260×540 |

| Weight (kg) | 2900 | 4300 |

Table of Contents

- drum chipper

- Drum type working principle of wood chipper

- Parameter table of industrial drum wood chipper

- Structural composition of industrial slicer

- The application scope of wood chipper industrial

- Video operation effect of wood drum chipper

- Types of wood chippers

- Drum Chipper vs. Disc Chipper: Which is Right for You?

- How to choose a wood chipper industrial?

- Chipper for sale: Comprehensive recommendations

Drum type working principle of wood chipper

The drum type chip cutting machine consists of a machine base, a knife roller, upper and lower feeding rollers, a conveying device, a hydraulic system, an electronic control system, and other parts

It is an equipment for producing process wood chips, widely used in industrial production such as density fiberboard, ordinary particleboard, and papermaking. As one of the main machines in the wood chip preparation section, it can also be used as a single wood chip production equipment.

- Cutting mechanism:

- Multiple flying knives are installed on the high-speed rotating drum (cutter roller) to achieve continuous cutting through the synergistic effect of centrifugal force and feed speed.

- The flying knife is made of high-strength alloy steel and fixed with special bolts and pressure blocks to ensure cutting stability.

- Feeding system:

- The upper and lower feeding rollers adjust the gap through a hydraulic system to adapt to different thicknesses of raw materials (such as logs, branches, and boards).

- The feeding speed can be adjusted to match the speed of the knife roller and control the length of the wood chips (usually adjustable from 20-38mm).

- Discharge and screening:

- The cut wood chips are discharged by wind or mechanical conveying, and the qualified chips fall through the sieve, while the large pieces automatically return for re cutting.

Parameter table of industrial drum wood chipper

| Model | Blade roller diameter (mm) | Inlet size (mm) | Weight (kg) | External dimensions |

| FD218 | 800 | 280×700 | 7000 | 2010*1950*1250 |

| FD2110 | 1000 | 330×1050 | 12500 | 2680*1950*1250 |

| FD213 | 1300 | 400×1250 | 18000 | 2870*2150*1500 |

Customize equipment according to customer needs

Structural composition of industrial slicer

- Main structure:

- Body: Welded with high-strength steel plates to support the operation of the entire machine, with strong impact resistance.

- Knife roller: diameter range of 300-2000mm, can install 2-42 flying knives, suitable for different production capacity requirements.

- Hydraulic system: The manual oil pump supplies oil, enabling the opening of the casing, replacement of blades, and adjustment of the gap between the feeding rollers, simplifying the maintenance process.

- Technical highlights:

- Modular design: Components such as feed inlet, knife roller, and discharge outlet can be independently disassembled to reduce downtime.

- Wear resistant blade: Made of alloy steel material, the lifespan is extended by more than 30%, and replacement does not require special tools.

- Safety protection: equipped with overload protection, emergency stop button and protective cover to reduce operational risks.

The application scope of wood chipper industrial

Suitable for a wide range of industries, such as mechanical charcoal factories, artificial board factories, biological granulation, papermaking, sawdust production, feed processing, breeding farms, mushroom cultivation bases, landscaping, etc., it is an ideal wood chip processing equipment for a large number of users.

- Paper industry: Provide uniform wood chips, optimize pulp efficiency, and reduce raw material waste.

- Artificial board manufacturing: High cutting accuracy ensures uniform particle board/fiberboard structure and enhances product strength.

- Biomass energy: converting forestry waste into fuel pellets to support the development of green energy.

- Non wood material processing: Suitable for bamboo, sugarcane, etc., expanding application scenarios (such as bamboo products, pulp and paper).

Video operation effect of wood drum chipper

The advantages of wood chipper

- Can save labor and improve work efficiency

- The surface of the chip is smooth, with low roughness and good surface quality, which can meet the specified specifications

- The chip cutting equipment has a compact structure, small footprint, simple operation, and convenient maintenance

- The cutting machine has low noise and less environmental pollution; High processing accuracy enables more precise processing

Types of wood chippers

Wood cutting machines can be divided into the following main types based on their structure, installation method, and feeding method:

- drum chipper

- Cutting mechanism: Several flying knives are installed on the rotating drum to cut wood at high speed. The outer edge of the drum has square through holes for easy discharge of wood chips.

- Raw material adaptability: Skilled in processing irregular raw materials such as branches, small diameter wood, and plywood with a diameter or thickness of less than 120 millimeters, and can also cut non wood materials such as bamboo and straw.

- Application scope: Paper mills, fiberboard factories, wood chip export bases, and biomass energy fields

- disc chipper

- Cutting mechanism: Cutting blades are installed on the cutterhead, which can directly cut wood by rotating the cutterhead. The extension of the blades can be adjusted to meet different specifications.

- Raw material adaptability: Suitable for processing regular logs with a diameter of 30-350 millimeters, with high cutting accuracy and better uniformity of wood chips than drum type.

- Application scope: Pulp and paper mills, high-density fiberboard production, and scenarios with high requirements for wood chip quality.

- Mobile chip cutting machine

- Features: It can be moved to forest areas for work, equipped with diesel engines or motors, and has strong flexibility.

- Application scenarios: Forest logging sites, small-scale wood chip processing sites, reducing raw material transportation costs.

Drum Chipper vs. Disc Chipper: Which is Right for You?

The most fundamental choice you will make is between a drum chipper and a disc chipper. They look different and produce slightly different results. Understanding this difference is key to matching the machine to your goals.

The Powerful All-Rounder: Drum Chippers

A drum chipper uses a large, heavy, rotating drum with chipping knives mounted on its surface. As logs and branches are fed in, the drum spins and the knives slice the wood into chips.

Drum chippers are the workhorses of the industry. Their main strength is their ability to process a wide variety of materials, including large-diameter logs, irregular tree limbs, scrap wood, and even demolition waste. They are less sensitive to the quality of the input wood. The chips they produce are excellent for biomass fuel, making them the top choice for the energy sector.

The Precision Specialist: Disc Chippers

A disc chipper features a large steel disc with knives mounted radially on its face. As the disc spins, wood is fed into it at an angle, and the knives slice it into very uniform, high-quality chips.

Disc chippers are all about chip quality and uniformity. If your end-product is for the pulp and paper industry or premium particleboard, a disc chipper is the superior choice. The chips it produces have a consistent size and thickness, which is a strict requirement for these applications. They are generally best for processing straight, clean logs rather than irregular branches or scrap.

| Feature Comparison | Drum Chipper | Disc Chipper | What This Means For Your Business |

|---|---|---|---|

| Input Material | Handles large, irregular wood, branches, scrap wood | Best for straight, uniform logs | If you process varied waste wood or forestry residue, a drum chipper offers more flexibility. |

| Chip Quality | Good, functional chips (ideal for fuel) | Excellent, highly uniform chips (for paper/pulp) | If you sell to a paper mill, you need a disc chipper. For a biomass plant, a drum chipper is more cost-effective. |

| Capacity | Generally higher throughput for bulk processing | High throughput, but optimized for quality | A drum chipper is built for maximum volume. A disc chipper is built for maximum quality. |

| Typical Use | Biomass plants, large-scale land clearing, sawmills | Paper mills, high-grade |

How to choose a wood chipper industrial?

To choose the perfect wood chipper, you must clearly define your raw material, your desired output chip, and your required capacity.

What is your raw material?

Are you chipping 50cm diameter hardwood logs, or are you processing small, twisted orchard branches? The size and type of your wood will determine the required infeed opening and the power of the machine. A machine designed for softwood logs will struggle with dense, hard tropical wood.

What chip size and quality do you need?

Talk to your potential buyers. Do they need 20mm chips for their boiler, or 10mm chips for their board press? The required output size will determine the setup of the knives and the screen inside the chipper. We can configure our machines to produce the exact size you need.

What is your required hourly capacity?

How many tons per hour do you need to process to run a profitable business? Be realistic. It’s better to invest in a machine that can handle your peak needs than to constantly run a smaller machine at its absolute limit. We offer models ranging from a few tons per hour to over 50 tons per hour.

Do you need an electric motor or a diesel engine?

An electric motor is cheaper to run and maintain and produces zero emissions, making it perfect for a fixed installation in a factory or sawmill. A diesel engine offers complete portability, allowing you to take the machine directly to the worksite.

Chipper for sale: Comprehensive recommendations

The drum chipper is a core piece of equipment in the wood processing industry, specifically designed to produce high-quality industrial wood chips. It is widely used in industries such as papermaking, particleboard, fiberboard, and biomass energy. The chipper produces industrial wood chips with uniform length, smooth edges, and consistent thickness, meeting the demands of large-scale production.

We are FUDE Machinery, a specialized manufacturer of wood processing equipment located in Zhengzhou, China. Since 2015, our 8,000 m² factory has produced high-quality, factory-direct machinery for over countries. We offer the full range of equipment, from wood chippers and crushers to complete pellet production lines and charcoal plants. Our team of 15 engineers is here to design a solution that works for you.

Contact us today for a free consultation and a detailed quote for your wood chipper project.

Fude Machinery-wood crusher manufacturer

Fude Machinery-wood crusher manufacturer