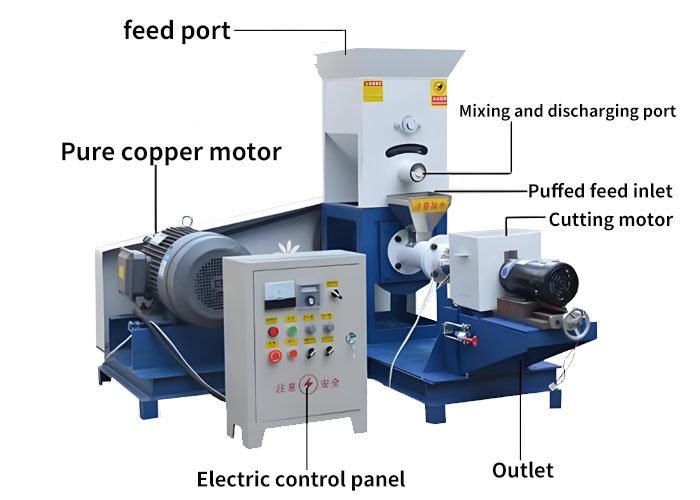

Aquatic shrimp and crab feed puffing machine

342The aquatic feed puffing machine is a specialized equipment that converts powdered raw materials into porous particles through high-temperature and high-pressure extrusion technology. It is mainly used to produce floating, sinking, and slow-re...

View details Fude Machinery-wood crusher manufacturer

Fude Machinery-wood crusher manufacturer

HelloPlease log in