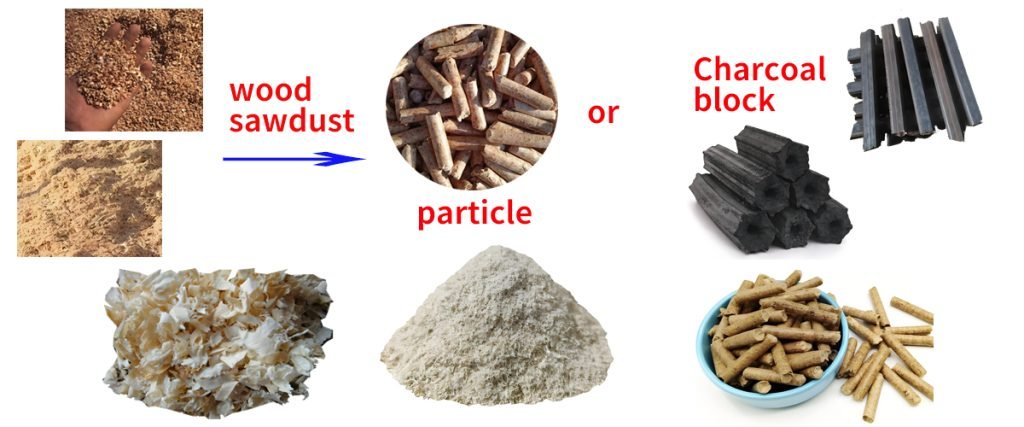

Sawmill waste is converted into fuel pellets

The process of making fuel pellets from sawmill waste includes collecting waste materials (such as sawdust, shavings, scraps, etc.), crushing, screening, drying, and then forming cylindrical pellets with a diameter of 6-12mm through high-pressure extrusion. Finally, they are cooled and packaged into finished products.

An Overview of Global Market of Fuel Pellets

The Global Wood Pellets Production:

- In recent years, the wood pellet production has increased greatly, but it is still small and fraught with uncertaintyas the international trade of wood pellets increases. And the global wood pellet production is far from meetingthe global market demand.

The Global Market Demand ofFuel Pellets:

- In the wake of high energy prices, consumers, businesses and regulators look for fuel alternatives to fossil fuels;and policies that promote the generation of renewable energy are spurring the use of fuel pellets as a substitutionfor coal in power plants. Therefore the global wood pellet demand is expanding rapidly.

Wood Pellets

Compared to other fuels in use today, wood pellets can be considered as a new type of fuel. Wood pellets areusually made from dry, untreated, industrial wood wastes like sawdust, shavings, or chip fines. The material iscompressed into small cylindrical pellets under high pressure by the wood pellet making machine. Wood pelletsare manufactured at wood pellet mills or wood pellet plants.

Advantages of Wood Pellets:

- The main feedstock is wood wastes.

- Featured with high energy density and consistency, fuel pellets make the international trade feasible.

- Neutral in terms of greenhouse gas emissions, which has made fuel pellets as an alternative to fossil fuel moreand more popular in boilers and power plants for electricity generation.

Energy Potential of Wood Wastes:

- Across the EU, it is estimated that wood wastes contributes about 6o T’Wh from Europe’s total biomass energy supply. Forestry by-products including sawdust, barks, etc. contribute about 38oTWh to the total energy supply.

Sources ofWood Wastes:

- Wood wastes sources are mainly organized in three major categories: forest biomass, wood processing residuaby-products and urban wood waste. And these wood residues can be divided into two types: logging residues and industrial wastes.

Potential of Making Fuel Pellets from Sawmill Residues

Stable Supply of Raw Material

- The above table of sources of wood wastes shows that 40% wood wastes come from sawmills, which means the sufficient supply of raw materials for making fuel pellets.

- Sawmills produce wood residues in the form of sawdust, chip fines, dry shaving, barks and trimmings etc.

- Generally speaking, a log in a sawmill produces 60 to 7o percent of useful timber as boards, 20-30 percent as wood chips, and 1o percent as sawdust.

- Sawdust can be generated in large quantities through the log saw-milling process.

- chip fines are created in sawmils where off-cuts and the round sides oflogs are diverted to a chipper.

- Shavings are created when saw timber is molded to specific section size. Shavings tend to be quite dry as timber is often seasoned before molding.

- Sawdust, chip fines and shavings have a desirable calorific value, moisture content for making fuel pellets.

The Development of Bio-energy Markets Provide Opportunity for Making Fuel Pellets fromSawmill Residues

- Due to mounting social and political pressure to reduce greenhouse gas emission, bio-energy products are of increasing interest to developers and regulators. The combustion of biomass for energy is recognized as beingneutral in terms of greenhouse gas emission. So the use of wood for bio-energy generation reduces energy carbonfootprint. This will be opportunities for sawmills and other wood processing businesses to access renewableenergy markets for the wood by-products they produce.

- The development of bio-energy markets provide opportunity for making fuel pellets from sawmill residues.

Application of sawdust pellet machine and sawdust pellet technology in granulation of sawdust by-products

- Besides large capacity wood pellet mill for commercial wood pellet plants, there are small scale fuel pelletmaking machine and portable wood pellet mill available to be used alongside sawmills to make fuel pellets atsite.

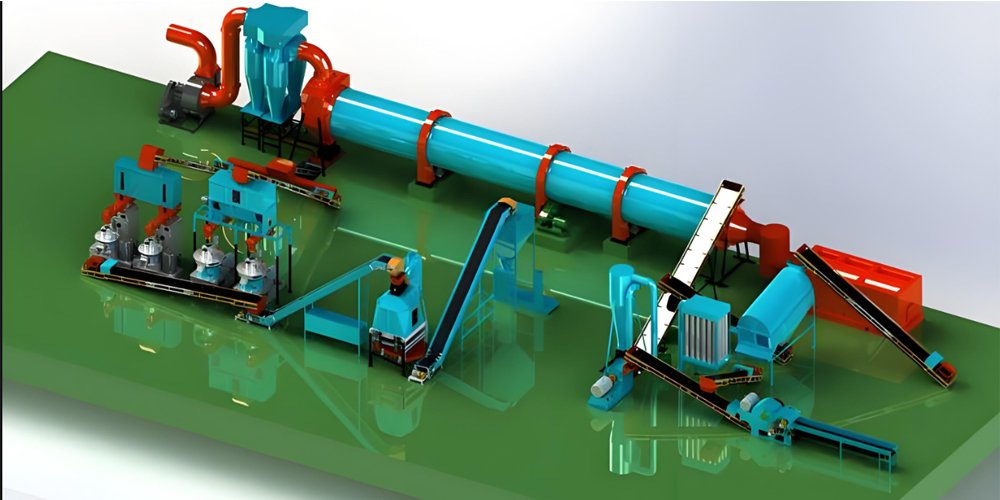

- The manufacturing process is determined by the raw material, but generally includes the following steps:grinding, drying, pelletizing, cooling, sifting and packaging.

Grinding and Drying ofSawmill Residues

Before sawdust, shavings or chips can be pelletized, it is vital that the size and the moisture content of thematerial are suitable. The proper size is less than 6mm and the suitable moisture content is about 1296-20%. So ifthe material size is larger, the hammer mill is necessary equipment; if the moisture content is higher than 20%use sawdust dr yer (you can use the moisture meter to measure the water percentage in raw materials), butremember that raw materials should not be too dry, the minimal level is 12%.

Pelletizing:

- Fuel pelletizing machine, also known as wood pellet mill or extruder, are available in different capacities. Thereare two types ot fuel pellet machine, namely, flat die wood pellet mill and ring die wood pellet mill. Flat diewood pellet mill can be driven by electric motor or diesel engine, and the flat die pellet mill, featured withsmall size, easy to move, easy operation and maintenance, is the preferred pellet making machine for sawmills topelletizing their own sawmill residues.

Cooling ofFinished Fuel Pellets:

- As the pellets leave the wood pellet mill, they are hot and soft. Thus they need to be cooled in the wood pelletcooler. The cooling process is important for the strength and durability of the pellets.

Screening ofPellets:

- The cooled pellets should be passed over a vibrating screen to remove fines among the pellets. These finematerial can be sent back to the pelletizing process. Once screened, pellets are ready to be packaged for thedesired end use.

Benefits of Making Fuel Pellets from Sawmill Residues

Generally the sawmill residues are piled or burned or sold in local markets for fuel. This way increases thestorage cost of sawmills and brings environmental pollution by burning directly. If turn these sawmill residuesinto fuel pellets, it can not only offer energy for sawmills themselves and save energy cost and storage cost ofsawmills but also benefits the environment.

Even the most modern sawmills find it difficult to convert half of the logs into wood, resulting in a large amount of wood residue. With the huge market demand for fuel pellets, the development of the bioenergy market, and the availability of pelletizing equipment and technology, there are broad opportunities to manufacture fuel pellets using these sawmill residues.

Zhengzhou Fude Machinery Equipment Co., Ltd. is a professional enterprise engaged in the research and development, production, and sales of wood pellet processing equipment. Committed to providing customers with efficient, stable, and reliable pre-sales and after-sales services.

Fude Machinery-wood crusher manufacturer

Fude Machinery-wood crusher manufacturer

HelloPlease log in