There are many coconut shell charcoal products on the market, but the quality varies greatly, this is because the charcoal processors have not mastered the method of processing high-quality coconut charcoal briquettes at the time of production. In particular, if the ash content of coconut shell charcoal briquettes is large, it will directly affect its price and sales. So, what can we do to reduce the ash content of coconut shell charcoal briquettes?

What is ash content of coconut charcoal briquettes?

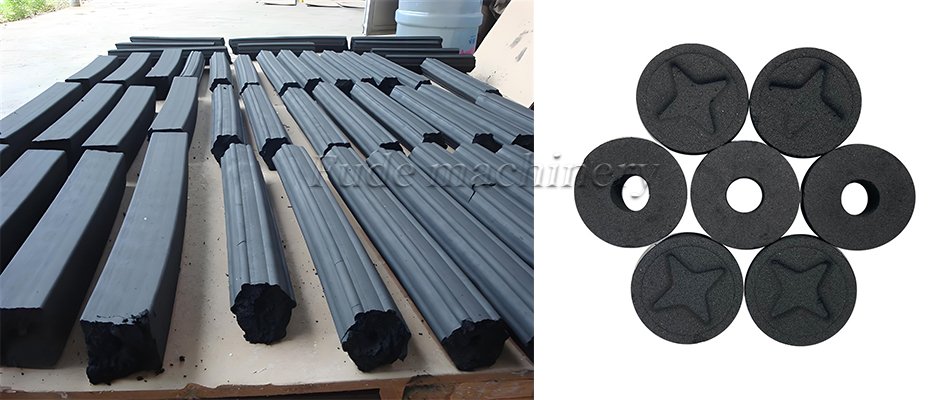

The most common coconut shell charcoal product on the market is hookah charcoal. Due to its high calorific value and long burning time, coconut shell charcoal is very suitable for processing various types of hookah charcoal.

The ash content of shisha charcoal represents the quality of shisha charcoal. Ash content refers to the percentage of the original hookah charcoal in the residue obtained after the hookah charcoal is fired at high temperatures.

Too much ash will reduce the burning time of hookah charcoal. Therefore, the smaller the ash content, the better the quality of the hookah charcoal. Good quality shisha charcoal requires that its ash content is not higher than 6% (weight basis).

Raw material selection and pretreatment

- Selected raw materials: choose coconut shells with low ash content as raw materials, avoiding the use of raw materials mixed with dirt, sand and gravel and other impurities. High-quality raw material is the basis for reducing ash.

- Thorough cleaning: fully clean coconut shells, remove the surface attached soil, sand and gravel and other inorganic impurities, reduce the source of ash.

- Crushing and sieving: Crush coconut shells to the right size and then sieve them to remove oversized or undersized particles to ensure the homogeneity of the raw material and avoid the mixing of impurities.

Production process control

- Control the carbonization temperature: In the process of carbonization, avoid too high temperature which will lead to the residual of inorganic components. Generally, the carbonization temperature is controlled between 400-600℃, and the specific temperature should be adjusted according to the characteristics of equipment and raw materials.

- Extend the charring time: Extend the charring time appropriately to ensure that the organic matter is fully decomposed and reduce the residual ash.

- Reduce the use of additives: avoid the use of additives containing inorganic components in the production process, if necessary, should choose low or no ash additives.

Methods to reduce the ash content of charcoal briquettes

First of all, we must choose high-quality charcoal. To ensure that charcoal briquettes have a low ash content, we must choose high-quality finished charcoal.

There are many raw materials for making charcoal, such as wood, rice husk, coconut shell, straw, and so on. However, the ash content of rice husk charcoal, straw charcoal, etc. is usually large. Therefore, it is best to use coconut shell charcoal, hardwood charcoal, etc. to process charcoal briquettes.

Secondly, we have to use adhesives wisely when processing charcoal briquettes. Before processing briquette charcoal with charcoal briquettes press machine, we usually pre-treat the charcoal powder by adding the appropriate amount of binder and water to the charcoal powder.

What we need to pay attention to is that there are many types of binders, and different binders have different effects on the ash content of coconut charcoal briquettes. Therefore, we should choose the adhesive with fewer impurities and pure texture as much as possible.

Our Fude Machinery production equipment includes: sawdust machine, branch crusher ,forced feed crusher, wood crusher, peeling machine, charcoal machine, charcoal machine production line, biomass pellet mill The company will continue to adhere to the “quality first, customer first” business philosophy, to provide customers around the world to provide higher quality wood equipment solutions.

Fude Machinery-wood crusher manufacturer

Fude Machinery-wood crusher manufacturer

HelloPlease log in