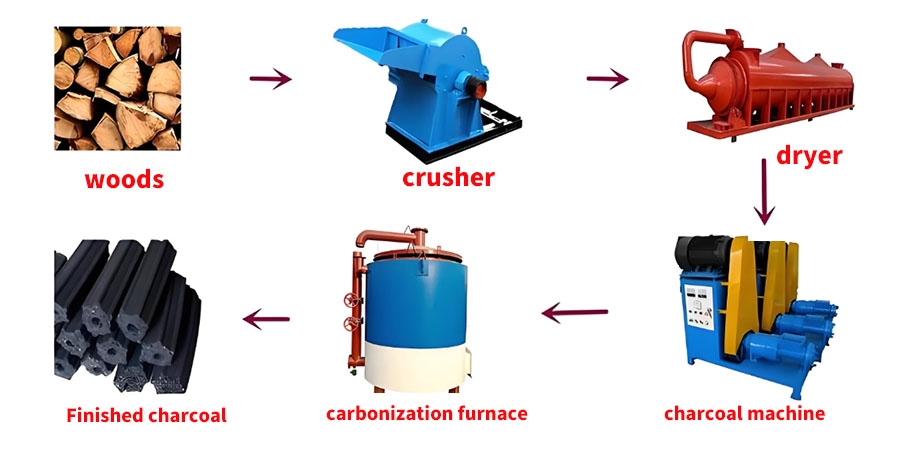

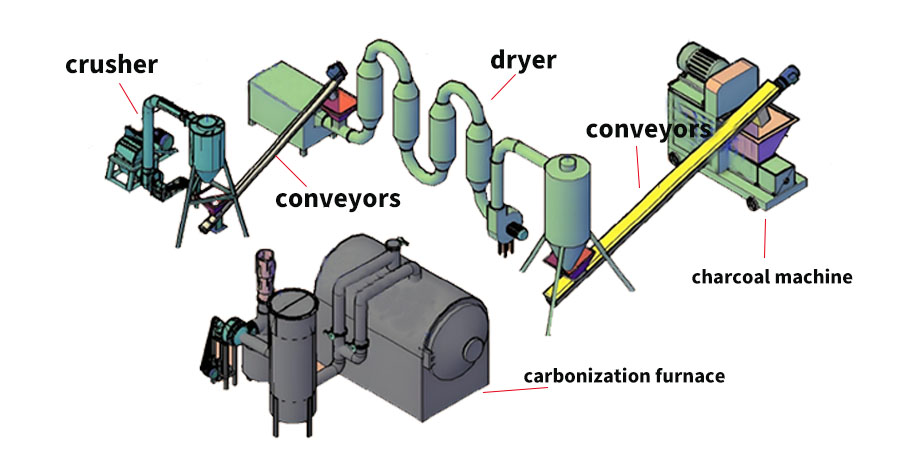

barbecue charcoal machine

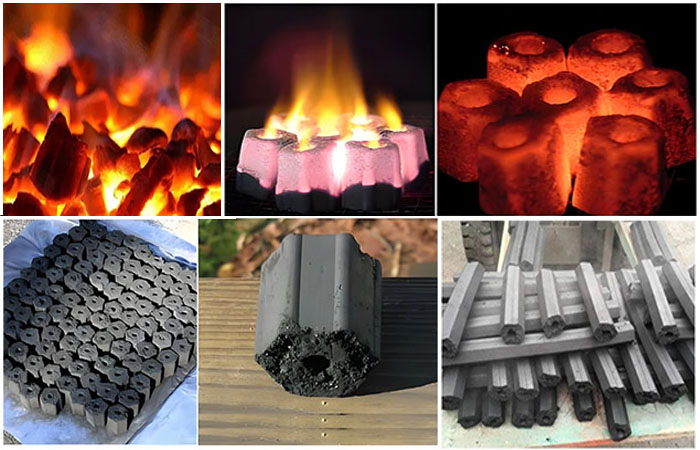

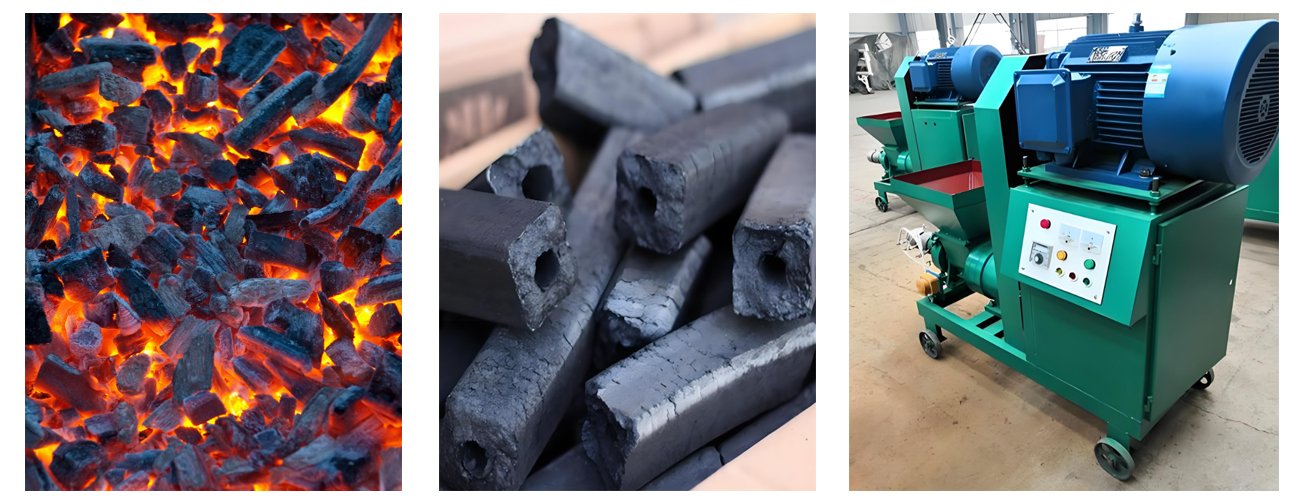

1708The bbq charcoal machine is made by using sawdust to be compressed at high temperature through rod making equipment. This product has high density and good combustibility, and can replace firewood and coal. The general product has an outer ...

View details Fude Machinery-wood crusher manufacturer

Fude Machinery-wood crusher manufacturer

HelloPlease log in