50 type charcoal machine shipped to Malaysia

784Charcoal rod making machine

View detailsSearch the whole station Products

In the thriving charcoal industry, the charcoal making machine price plays a crucial role for charcoal producers and manufacturers. The affordability and cost-effectiveness of these machines directly impact the profitability and competitiveness of businesses. In this article, we will explore the factors that influence charcoal making machine prices and highlight the comparative advantages of Fude Machinery charcoal machines.

The price of charcoal making machines has a significant impact on the operations and profitability of wood charcoal processing businesses. Affordable machines allow small and medium-scale producers to enter the market, fostering competition and innovation.

Additionally, cost-effective machines help improve production efficiency, reduce labor costs, and enhance overall profitability. However, high-quality machines often come with a higher price tag, reflecting their advanced features, durability, and productivity.

The charcoal making machine price is influenced by various factors, including:

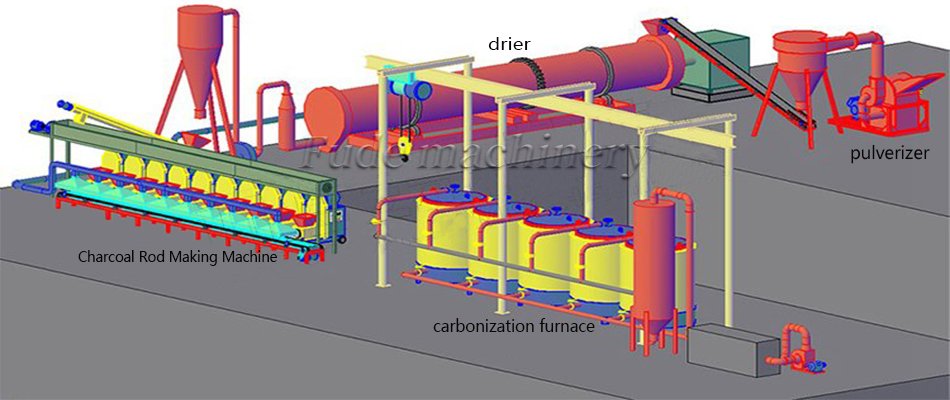

The working principle of the charcoal making machine is mainly to convert biomass raw materials such as wood into charcoal by means of high-temperature anoxic pyrolysis. Specifically, the raw materials are sent into the charcoal furnace of the machine, and the temperature inside the furnace is gradually increased to about 300℃ – 700℃ by the heating device in an airtight environment, while the oxygen content inside the furnace is strictly controlled so that it is in the state of anoxia. Under these conditions, the water in the raw material is first evaporated, then the organic matter undergoes thermal decomposition, and the volatile substances (e.g., tar, wood vinegar liquid, etc.) are precipitated and discharged through the pipes, while the remaining carbon elements are gradually enriched and solidified, and eventually form charcoal with a porous structure. The whole charring process usually takes several hours, depending on the type and size of the raw material and the operating parameters of the machine.

The main reasons for choosing charcoal making machine are its high efficiency, environmental protection and economic advantages. It rapidly converts biomass raw materials into charcoal through automated processes, significantly shortening the production cycle and increasing the output, which is more efficient than the traditional earth kiln charring; the production process adopts a closed and anoxic environment, which effectively reduces the emission of harmful gases and meets the requirements of environmental protection, and at the same time, the recovered by-products, such as tar and wood vinegar liquid, can also create additional income; in addition, the equipment is easy to operate and has a low energy consumption, which reduces the cost of manpower and energy. In addition, the equipment is easy to operate and has low energy consumption, which can reduce labor and energy costs, especially suitable for large-scale production or resource reuse projects, with significant comprehensive benefits.

Fude Machinery factory has gained a reputation for its high-quality charcoal making machines, which offer several comparative advantages over competitors. With years of experience and expertise, Fude Machinery ensures the following benefits for its customers:

The price of charcoal production machines directly impacts the profitability and competitiveness of the charcoal industry. Charcoal producers must consider the balance between affordability and quality when investing in these machines.

Fude Machinery factory stands out as a reputable manufacturer with its competitive pricing, advanced technology, and customizable options.

By understanding the factors influencing machine prices, businesses can make informed decisions and secure reliable and efficient charcoal making machines to boost their operations and success in the market.

It can produce charcoal sticks of various specifications and shapes

View detailsThere are many safety issues that need to be paid attention to during the production process of charcoal

View detailsCharcoal grinder equipment is an integral part of the charcoal production process, responsible for pulverizing charcoal into fine powder that can be used for various applications, including briquette making, agriculture, and industrial purposes. ...

View details

HelloPlease log in