What specifications of charcoal sticks can be produced by a coal rod machine

586It can produce charcoal sticks of various specifications and shapes

View detailsSearch the whole station Products

Charcoal extruder machines have gained significant popularity in the biomass briquette industry due to their efficiency and versatility. Here, we explore the profitability and business opportunities associated with utilizing charcoal extruder machines for producing charcoal briquettes. We will discuss the key advantages of using these machines, potential market demand, and the financial aspects involved in setting up a charcoal briquette production business.

Charcoal briquettes extruder machines offer several advantages that contribute to their profitability and success in the market. These include:

The market demand for charcoal briquettes has been steadily increasing due to their eco-friendly nature and diverse applications. Industries such as cooking, heating, and metallurgy have a growing demand for clean and sustainable fuel alternatives. This presents a lucrative business opportunity for entrepreneurs considering venturing into the charcoal briquette industry.

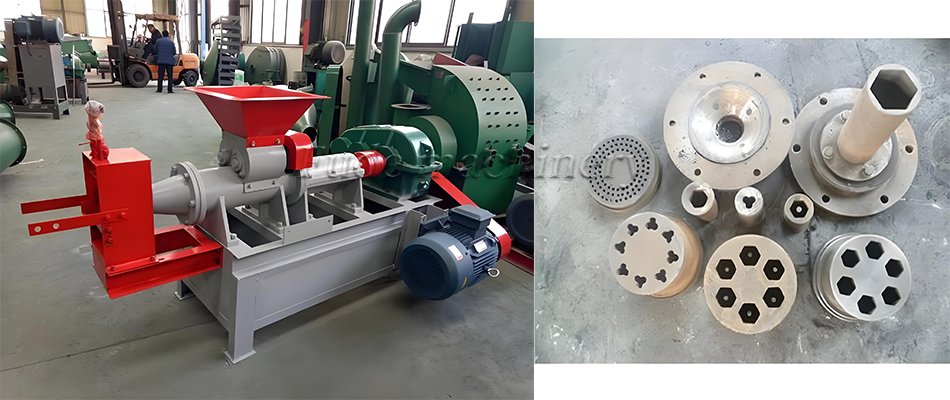

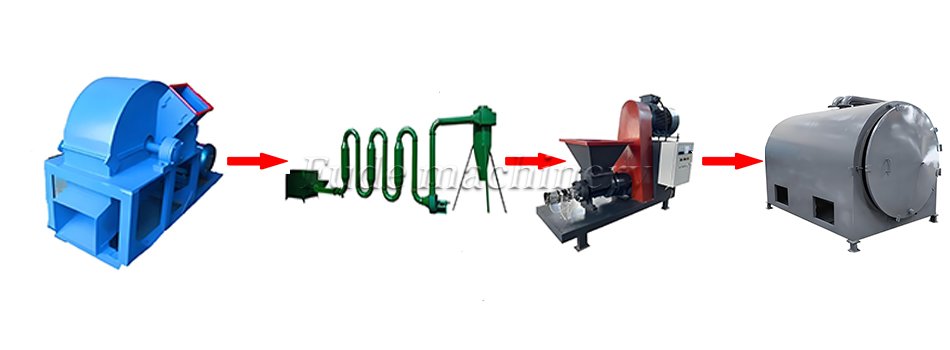

The working principle of charcoal making machine is to send granular biomass raw materials such as bamboo sawdust, peanut shells, straw and other granular raw materials with moisture content lower than 12% into the forming cylinder under the action of spiral propeller and heating ring, soften the lignin in raw materials and produce viscosity through high temperature and high pressure environment, and then tightly combine the loose raw materials under the action of mechanical extrusion to finally form the rod-shaped solid fuel with center hole. In this process, the raw materials do not need to add any binder, and the optimized design of the forming cylinder structure can reduce the friction, together with the automatic temperature control device to ensure that the density of the rods is uniform, the surface is smooth and without cracks, and the finished rods can be transformed into mechanism charcoal after the subsequent carbonization treatment.

he profitability and business opportunities with charcoal extruder machines are significant in the growing market for charcoal briquettes.

By leveraging the advantages of these machines, identifying market demand, and implementing a well-planned business strategy, entrepreneurs can establish a successful venture in the charcoal briquette industry.

Remember to stay updated on industry trends, continuously improve product quality, and adapt to changing customer preferences to sustain growth and profitability.

It can produce charcoal sticks of various specifications and shapes

View detailsChoosing and configuring a charcoal machine is a key step in ensuring charcoal production efficiency and product quality

View detailsCharcoal rod making machine

View detailsWood biochar briquettes are an eco-friendly and sustainable fuel source derived from waste wood materials. These briquettes serve as an excellent alternative to traditional fossil fuels, offering both environmental and economic benefits. The prod...

View details

HelloPlease log in