wood pellet maker machine

Small particle machine

| Model | 150 |

| Power (KW) | 4.5 |

| Output (kg/h) | 100-200 |

| Voltage (v) | 220/380 |

| Product Features | The maquina de pellets de alimento to the granulation and shaping equipment, which is made of corn, soybean meal, rice straw, and rice husk Poultry feed processing machinery. |

Table of Contents

- Definition of feed pellet machine

- Feed pellet machine parameter table: customization supported

- Video operation effect of maquina para hacer pellet

- Working principle of pellets machine

- Why do we need a feed pellet machine

- Applicable scope of wood pellet maker machine

- How to choose a small wood pellet machine?

Definition of feed pellet machine

A feed pellet machine is a mechanical device that crushes raw materials such as corn, soybean meal, straw, forage, and rice husk, and then extrudes them into granular feed through physical compression. Its core functions include:

- Wide adaptability of raw materials: can handle single or mixed raw materials, such as crop straw, grain processing by-products, grass, etc.

- Particle molding stability: Through mold compression, particles with a diameter of 2.5-20mm and adjustable length are produced to meet the needs of different animals.

- Nutrient retention and enhancement: The high-temperature and high-pressure molding process can kill parasitic eggs and pathogenic microorganisms, while denaturing the trypsin resistance factors in grains, improving feed digestibility.

- Convenient storage and transportation: Granular feed has a low moisture content (usually ≤ 12%), is not easy to mold, and is convenient for long-term storage and long-distance transportation.

Feed pellet machine parameter table: customization supported

| Model | Power (kW) | Yield (kg/h) | External dimensions | Flat mold speed |

| 150 | 3-4 | 70-200 | 820*310*750 | 320 |

| 160 | 4-4.5 | 150-250 | 850*310*780 | 370 |

| 210 | 7.5 | 400-500 | 1100*450*930 | 370 |

| 260 | 15 | 400-700 | 1240*530*1190 | 370 |

Electric feed pellet machine

Diesel version feed pellet machine

Video operation effect of maquina para hacer pellet

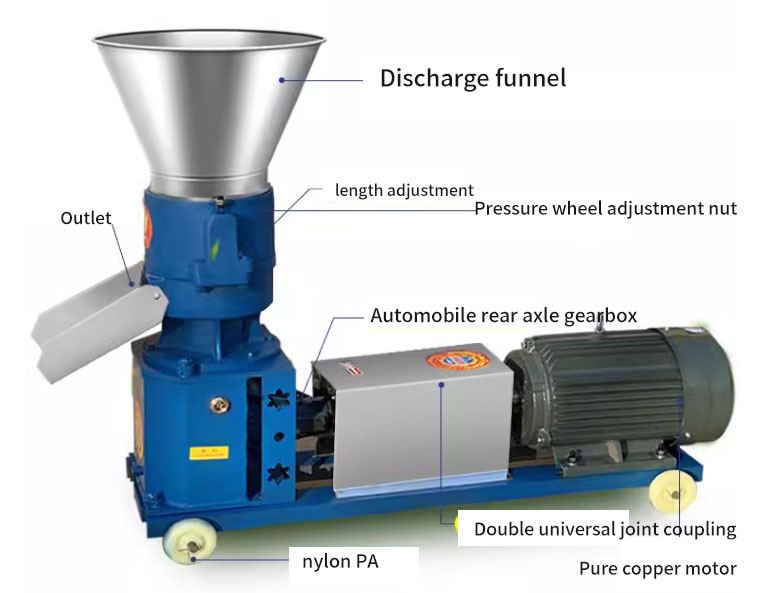

maquina para hacer pellets, also known as small household feed pellet machine. The production capacity is 100-1000 kilograms per hour, based on the principle of circular motion. The template and pressure roller are made of high-quality alloy steel and specially treated. The main shaft and flat mold are driven by friction to rotate the pressure roller. The material is gelatinized at high temperature between the pressure roller and the template, and the protein solidifies and denatures. It is discharged from the mold hole under radial compression. The particles made are sent out of the machine through a throwing plate, and the particle length can be adjusted through a cutting edge.

Working principle of pellets machine

- Preparation of raw materials: Mix the crushed materials of crops such as corn, soybean meal, straw, and grass according to a certain proportion of ingredien

- Extrusion molding, the raw materials are fed into the feed hopper of the feed pellet machine, and then compressed through the spiral extrusion device in the compression chamber.

- Mold pressing, under high pressure, the raw materials are forced to pass through the small holes of the mold, forming fixed shaped particles.

- High temperature treatment, the heating element inside the mold chamber causes the raw materials to form pellet feed under high temperature and pressure.

- Cutting and discharging, the pellet feed is divided into particles of consistent length through the cutting device and discharged through the discharge port.

Why do we need a feed pellet machine

| 1,Simple structure, wide adaptability, small footprint, and low noise. 2,Powdered feed and grass powder can be granulated without the need for or a small amount of liquid addition, so the moisture content of pellet feed is basically the moisture content of the material before granulation, which is more conducive to storage. 3,Chicken, duck, fish, etc. can achieve higher economic benefits than mixed powdered feed. 4,Dry material processing produces feed particles with high hardness, smooth surface, and internal ripening, which can improve the digestion and absorption of nutrients. 5,The process of particle formation can cause denaturation of pancreatic enzyme resistance factors in grains and beans, reduce adverse effects on digestion, kill various parasitic eggs and other pathogenic microorganisms, and reduce various parasitic and digestive system diseases. |

Applicable scope of wood pellet maker machine

| It can be used to process feed pellets for livestock, poultry, sheep, chickens, rabbits, fish, and other aquatic products. It can also be used to process some coarse fiber pellets, such as wood chips, rice husks, weeds and other crop straw, household waste, factory waste and other materials with low adhesion rate that are difficult to form, as well as some organic fertilizers, compound fertilizers and other low-temperature granulation. |

Application scenarios and economic benefits

- Poultry farming: Granular feed can reduce feed waste and increase the feed intake and growth rate of chickens, ducks, and geese.

- Ruminant animals: After consuming pellet feed, the rumen fermentation efficiency of cattle and sheep is improved, and daily weight gain increases by 10% -15%.

- Aquaculture: Floating pellet feed is easy to observe the feeding amount, while settling pellets can reduce water pollution.

- Straw utilization: Agricultural waste such as corn straw and wheat straw is converted into feed pellets, and each ton of straw can replace 0.3 tons of grain, reducing breeding costs by more than 30%.

- Biomass energy: By adjusting the mold and process parameters, biomass fuels such as sawdust particles and rice husk particles can be produced, with a calorific value of 4000-4500 kcal/kg.

How to choose a small wood pellet machine?

| straw pellet machine, divided into ring mold feed pellet machine, flat mold feed pellet machine, and roller feed pellet machine, also known as feed pelletizer or pellet feed forming machine, belongs to feed pelletizing equipment. It is a feed processing machinery that uses corn, soybean meal, straw, straw, rice husk, etc. as raw materials, and directly presses them into pellets after crushing the raw materials. |

Fude Machinery-wood crusher manufacturer

Fude Machinery-wood crusher manufacturer