Which industries are suitable for using a wood drying oven

468Wood drying oven has been widely used in multiple industries due to its wide applicability and significant advantages.

View detailsSearch the whole station Products

If you run a plywood factory, Every day, your operation generates mountains of wood residue: sawdust from sanding, veneer clippings, core cut-offs, and edge trimmings. For most factories, this waste represents a significant cost and a logistical headache for disposal.

At FUDE Machinery, we see this differently. We see your “waste” as a consistent, high-quality, and completely free raw material for a new, highly profitable business venture: a wood pellet production line. This is not just about recycling; it is about creating a valuable, saleable commodity from a resource you already have. This guide will show you exactly how our integrated systems can transform your factory’s byproduct into a powerful new revenue stream.

Plywood waste is one of the best raw materials for making pellets because it is clean, consistent in quality, and has a relatively low moisture content to begin with. Unlike raw forest wood, your factory’s waste stream is predictable and uniform. This makes the pelletizing process much easier to control, leading to a higher quality final product.

| Type of Plywood Waste | Characteristics | Suitability for Pellets | What This Means for You |

|---|---|---|---|

| Sander Dust | Very fine, dry powder. | Excellent. This is the perfect size and often has ideal moisture. It may not even need crushing or extensive drying. | This is your highest-value raw material. It can be fed directly or with minimal processing into the pellet mill, dramatically reducing production costs. |

| Veneer Clippings | Thin, dry sheets and scraps. | Excellent. Very easy to process. Needs to be put through a wood crusher to reduce its size, but it pelletizes perfectly. | You can collect all veneer waste and easily convert it, eliminating a significant portion of your factory’s solid waste volume. |

| Core & Edge Trims | Irregular small blocks and strips of wood. | Excellent. This material is high-density and clean. It requires a robust crusher to turn it into sawdust, but it produces very high-quality pellets. | This allows you to achieve nearly 100% utilization of the wood that enters your factory, turning every last scrap into a saleable product. |

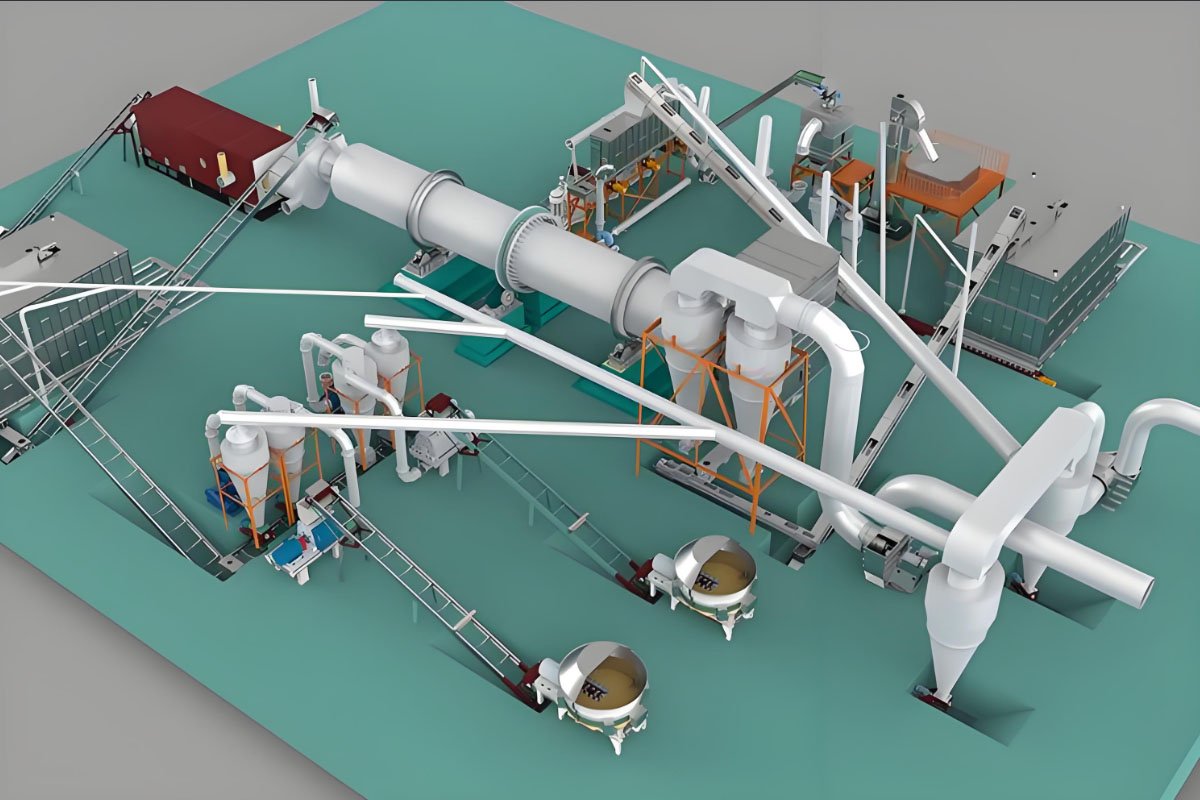

At FUDE Machinery, we design a complete, automated system to handle this conversion. The process is logical and highly efficient, designed to run with minimal labor. A complete pellet plant ensures a smooth flow from your factory floor to a bag of finished pellets.

To successfully convert plywood waste, you need a carefully integrated system of machines, not just a standalone pellet mill. Buying the right combination of equipment ensures there are no bottlenecks and that the quality is consistent. As a one-stop-shop manufacturer, we provide the complete, synchronized solution.

Here is the essential equipment list for a plywood pellet plant:

Question 1: Does the glue in the plywood affect the quality of the wood pellets?

This is the most important question. For pellets intended for industrial boilers and power plants, the small amount of urea-formaldehyde or phenolic resin glue is generally not an issue and is accepted. However, for the premium residential heating market (ENplus A1 standard), pellets must be made from virgin wood with no additives. You should target the industrial fuel market, which is large and growing.

Question 2: What is the typical return on investment (ROI) for a plywood pellet plant?

The ROI is extremely attractive. Because your raw material cost is zero (you are using waste), your only major costs are electricity and labor. Most of our clients see a full return on their investment within 12 to 24 months, after which the plant becomes a pure profit center.

Question t3: Can I start with a small system and expand it later?

Yes, absolutely. Our complete pellet plants are designed to be modular. You can start with a smaller capacity line (e.g., 500 kg per hour) to serve local customers and then easily add a second pellet mill and ancillary equipment to double your capacity as your business grows.

Question 4: Do I need a lot of extra space in my factory?

The footprint of the plant depends on the capacity. A small-to-medium line (500 kg/h to 1 ton/h) can typically be installed in a space of 200-400 square meters (2,000-4,000 sq ft). We provide a custom layout design to make the most efficient use of your available space.

For a plywood factory, wood waste is not a liability to be disposed of; it is a valuable asset waiting to be monetized. A wood pellet production line is the most direct and profitable way to unlock that value. It transforms an operational cost into a consistent and reliable new revenue stream, improves your factory’s environmental footprint, and creates a valuable product that is in high demand in the global energy market.

The key to success is a well-designed, fully integrated system that is tailored to the specific types and volumes of waste your factory produces. This is where our expertise comes in.

About FUDE Machinery

FUDE Machinery is a world-class manufacturer of biomass processing solutions. Since 2015, from our 8,000 m² facility in Zhengzhou, China, we have helped businesses in over 120 countries turn their waste into value. Our engineering team specializes in designing custom, turn-key pellet plants that are efficient, reliable, and profitable.

Contact our engineering team today for a free consultation and a custom proposal for your own plywood pellet plant.

Wood drying oven has been widely used in multiple industries due to its wide applicability and significant advantages.

View detailsIt is mainly used to convert various waste materials into efficient and environmentally friendly fuel particles

View detailsWood crushers are widely used in various fields such as wood processing, biomass energy, agriculture, environmental protection, and greening

View detailsWood powder crusher is widely used in various fields such as wood processing, feed production, biomass energy utilization, and paper industry

View details

HelloPlease log in