What is a wood crusher production line

399The wood crusher production line is an efficient, environmentally friendly, and multifunctional combination of wood processing equipment

View detailsSearch the whole station Products

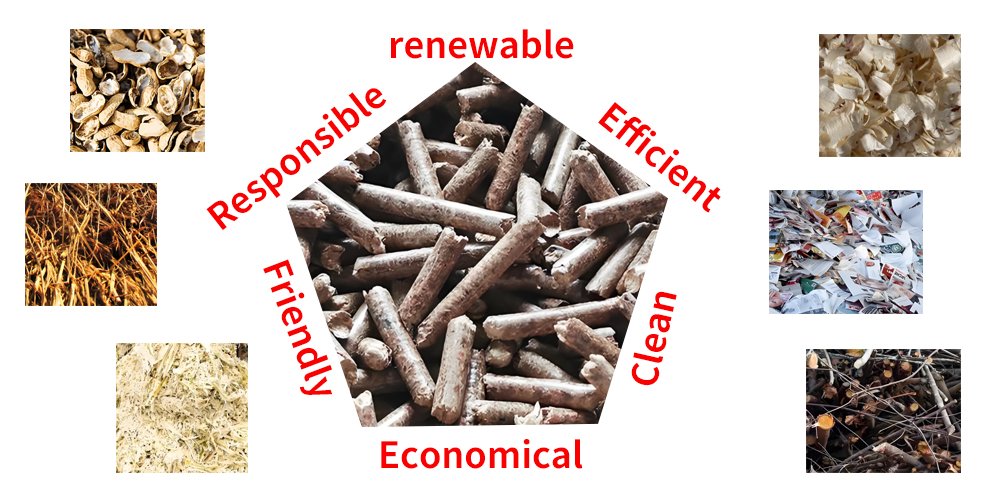

Biomass pellets are solid fuels made from biomass materials such as agricultural and forestry waste through processes such as crushing, drying, and pressing. They have the advantages of being environmentally friendly, efficient, and renewable. The production process mainly includes steps such as raw material collection and pretreatment, crushing, drying, pressing, cooling, and packaging. The raw materials usually include wood processing waste, straw, rice husk, etc., and the moisture content needs to be controlled between 10% -15% to improve the molding effect. During the pressing process, cellulose and lignin are tightly combined through a granulator at high temperature and high pressure to form dense particles. After cooling, sieve and package to ensure particle quality and stability. Biomass pellets are widely used in heating, power generation, industrial boilers and other fields, and are an important force in promoting the development of green energy.

agricultural waste:crop stalk and straw material, rice huskcotton stalk, coffee husk, alfalfa straw, coconut shell,palm shell, sugarcane bagasse, etc.

forestry residue: sawmill residue, branches, bark, leaves,etc.

solid waste: junk paper, waste plastic, cardboard,etc.

building heating: Biomass pellets can be used in a pellet stove or furnace to heating room at school, hospital.marketplace, company, etc, Cooking with biomass pellets is also available.

industrial boiler: Bio-pellets can partly(or entirely) replace coal or fossil fuel in co-firing heating for large-scaleindustrial operation to reduce the energy cost.

power plants :Biomass pellets can be used in power plants to solve the problem of insufficient power supply.

animal bedding:Bio-pellets made of softwood is a kind of slap-up animal bedding to raising animal experience.

Generally speaking, any material can be converted into biomass particles through the particle mechanism, as long as it can burn. The traditional materials for fuel pellets are sawdust, shavings, sawdust from sawmills, or forestry residues such as tree branches, bark, and leaves. Therefore, these particles are called wood chips. With the surge in demand for biofuel pellets, various agricultural wastes have been developed to produce biomass pellets. Corn straw particles, straw particles, rice husk particles, coconut shell particles, and sugarcane bagasse particles can all be listed in this category of particles. There are also paper particles and plastic particles made from municipal solid waste.

Biomass pellets are a clean fuel made from agricultural waste, wood processing residues, and other materials, with advantages such as high efficiency, environmental friendliness, and renewability. Its application fields are extensive, covering multiple aspects such as industry, agriculture, civilian use, and environmental protection. In the industrial field, biomass pellets can replace coal as boiler fuel for power generation, heating, drying, etc., reducing pollution emissions; In the field of agriculture, it can be used for greenhouse heating, soil improvement (using ash residue as potassium fertilizer), and animal feed; In the civilian field, as a fuel for home heating, fireplace, barbecue, etc., it is easy to operate and has high thermal efficiency; In addition, it can also be used to produce derivative products such as biochar, activated carbon, bioplastics, biofuel oil, etc., promoting circular economy and sustainable development.

The market demand for biomass pellets is experiencing significant growth, driven by multiple factors including global emphasis on sustainable energy, strengthening environmental policies, the demand for alternatives to traditional fossil fuels, and technological innovation.

According to multiple reports, the global biomass pellet market is expected to continue growing in the coming years. For example, the global biomass pellet market sales reached 60.2 billion yuan in 2023 and are expected to reach 100.4 billion yuan by 2030, with a compound annual growth rate (CAGR) of 7.5%. In addition, another report pointed out that the global biomass pellet market sales in 2023 were 9.473 billion US dollars, and it is expected to increase to 14.8 billion US dollars by 2030, with a compound annual growth rate of up to 7.5%. These data indicate that biomass pellets, as an important component of renewable energy, are becoming a key driving force for the global energy transition.

The emphasis placed by governments around the world on reducing carbon emissions and addressing climate change is an important factor driving the growth of the biomass pellet market. For example, countries and regions such as China, the European Union, and the United States have introduced policies to encourage the use of renewable energy and promote the widespread application of biomass pellets as clean energy. China’s policies such as the Renewable Energy Law and the Medium – and Long Term Development Plan for Renewable Energy have provided a favorable development environment for the biomass pellet industry. In addition, the EU’s carbon neutrality goal (achieving carbon neutrality by 2050) has also prompted member states to increase investment in biomass energy.

Europe is the world’s largest market for biomass pellets, while the biomass pellet market in North America is rapidly developing. The Asia Pacific region is an important area for the growth of the biomass pellet market. With the increasing global energy demand, countries such as India and Brazil have surplus agricultural waste, providing sufficient raw materials for biomass pellet production.

The market demand for biomass pellets is experiencing significant growth, driven by multiple factors such as environmental policies, demand for traditional energy alternatives, technological innovation, and policy support. In the future, with the adjustment of global energy structure and the promotion of sustainable development goals, biomass pellets will play an increasingly important role in the global energy transition. Despite facing some challenges, with technological advancements and strengthened policy support, the biomass pellet market will continue to maintain a growth trend, providing strong support for achieving sustainable development goals.

Biomass pellet is one kind of biofuel resources. Biofuel or biomass energy, refers to renewable energy sources such as solar energy,wind energy,etc which can both generate heat or electricity for human life and produce little damage to the environment at the same time. Bio-pellets is commonly make by biomass pellet machine with the biomass materials. Before turning into pellets,a series of processes, including crushing to required sizereducing water content, pelletizing, cooling, packaging,are needed. After processing, the combustion andautomation operation performance of biomass materials has been increased sharply. With features of highcombustion value,uniform size, biofuel pellets have wide range application in boiler, stove, power plants.factories and household heating,etc. As the biomass energy is recognized by more and more people, bio-pelletshares an increasing percent in fuel market, That is to say, biomass pellet industry is a sunrise industry which isworth investing.

In terms of biomass pellet production, the pellet machines and related equipment provided by Zhengzhou Fude Machinery can meet the needs of different scenarios, such as breeding farms, industrial production, household use, etc.

The wood crusher production line is an efficient, environmentally friendly, and multifunctional combination of wood processing equipment

View detailsFish farming needs good feed. Bad feed wastes money and hurts fish health. What is the best feed choice? The best fish feed depends on the fish species, age, and farming goal. It needs balanced nutrients, high digestibility, and often comes as ...

View detailsCarbonization furnace is a multifunctional, efficient and environmentally friendly equipment

View details

HelloPlease log in